Interested in Membrane Solutions?

Please reach us using the Contact Us button below and we will get back to you quickly.

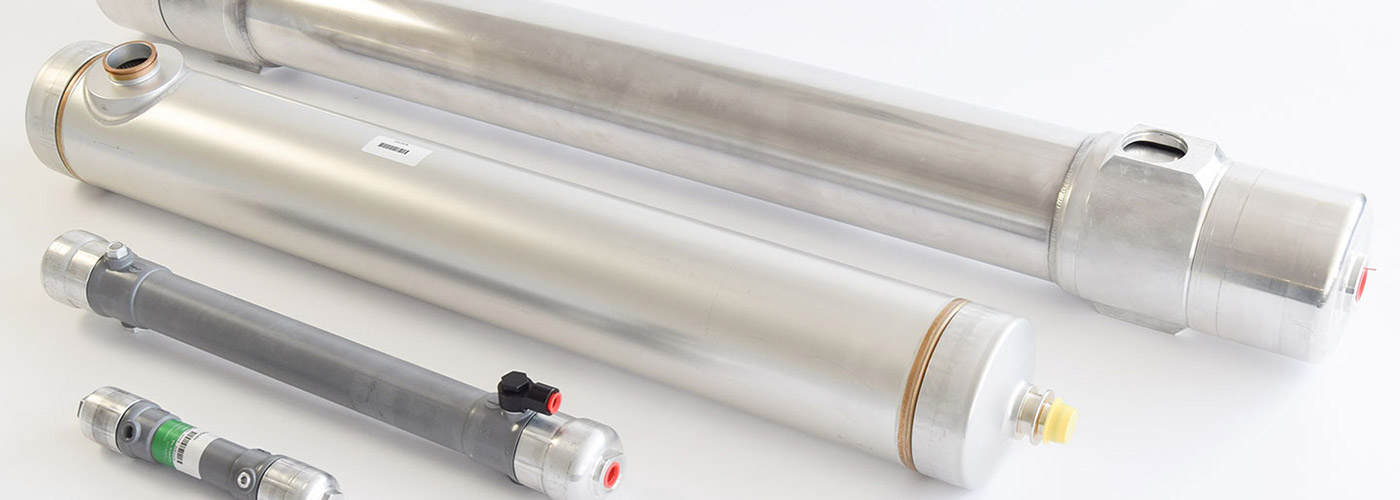

A pioneer in membrane separation technology since 1979, Air Products Membrane Solutions specializes in the development of high-efficiency, high-productivity hollow fiber membrane separators and systems for on-site gas generation. Our full portfolio of PRISM® Membrane Separators is designed to be packaged into systems that help protect lives and goods on land, sea, and in the air, create more sustainable energy sources, and raise productivity across a variety of industries and applications.