Get in touch with our technical experts.

Contact Air Products to put decades of cold spray experience to work for you.

.jpg?as=0&w=969&hash=EAFA92DAA1714180487FE957C6C64AB4)

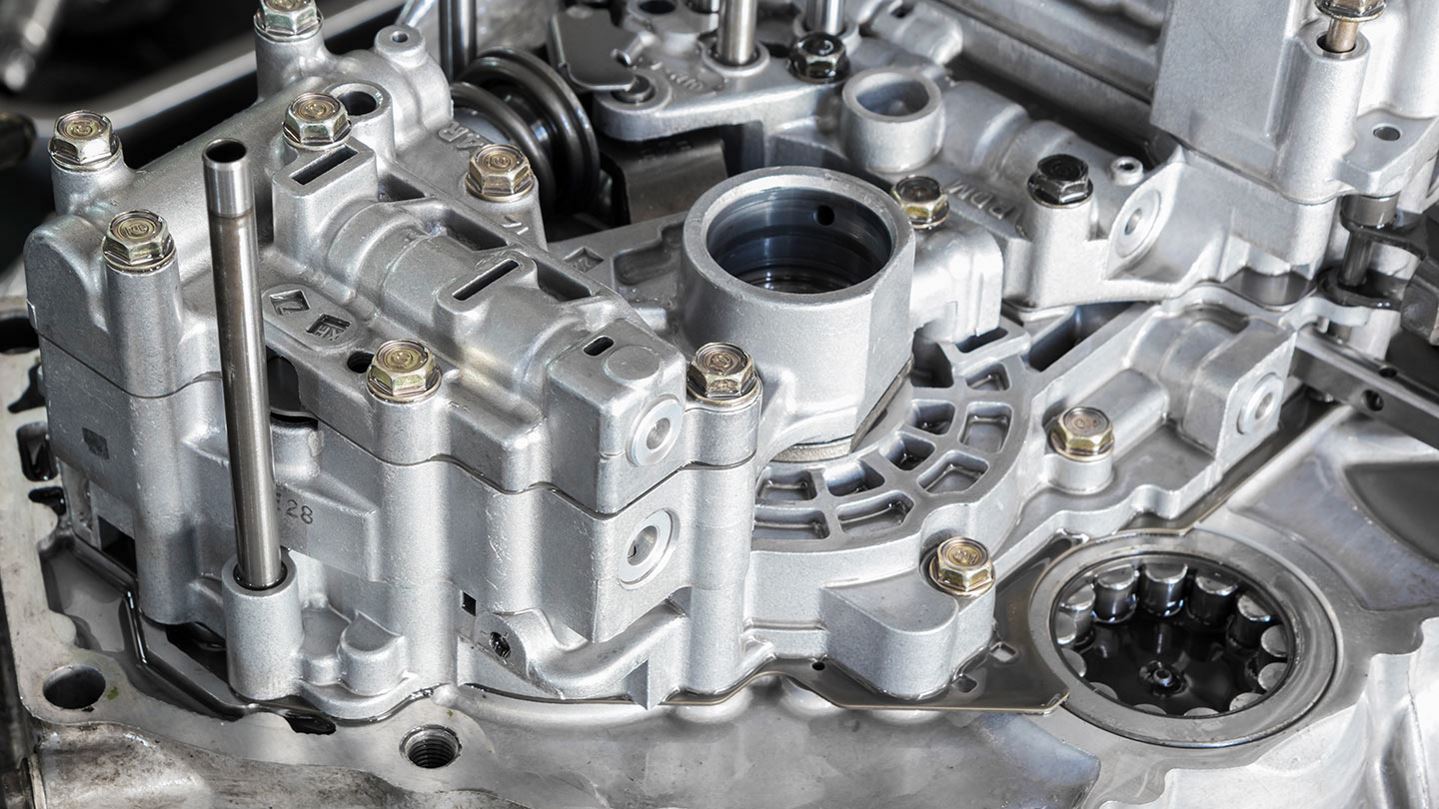

Cold Spraying Solutions and Expertise

- Helium – high heat transfer coefficient and thermal conductivity, and allows a significantly higher sonic velocity than nitrogen; used as a carrier gas in cold spray applications.

- Nitrogen – a economical powder carrier gas in cold spray applications.

- Our application engineers can help you select a supply system to meet your pressure and volume requirements.

Industrial Gas Audits and Leak Detection Services

Audits and leak detection services can be comprehensive assessments of the entire gas supply system, or specific to gas or process equipment that use the gas.

Additional Services Gases

Air Products gases, typically provided in gaseous and liquid form, enable customers in a wide range of industries to improve their environmental performance, product quality, and productivity.

Helium

An inert gas for cryogenic, heat transfer, shielding, leak detection, analytical and lifting applications

Nitrogen

Useful as a gas, for its inert properties, and as a liquid for cooling and freezing. Virtually any industry can benefit from its unique properties to improve yields, optimize performance and make operations safer.