Learn how Air Products applies hydrogen fueling solutions to a variety of industries and applications, like hydrogen trucks, hydrogen cars, and more.

industry-leading TECHNOLOGIES

Global leader of technical options for capturing CO₂ from fossil fuel conversion before it reaches the atmosphere, key to Carbon Capture and Sequestration.

Premier provider of turnkey solutions to convert hydrocarbon feedstock into synthesis gas for high-value products.

Pioneer in gas membrane separation for commercial use with early projects commissioned in 1977 and full-scale commercialization in 1979.

Rotoflow is both a pioneer and leader in turboexpander technology for the hydrocarbon, LNG, petrochemical, and industrial gas markets.

Pioneer in air separation technology with unparalleled experience in designing, engineering, constructing and operating cost-effective gas supply systems.

Leading provider of carbon monoxide and syngas supply and technology solutions.

The world's future depends on low- and zero-carbon solutions. Air Products' hydrogen is key to accelerating the energy transition.

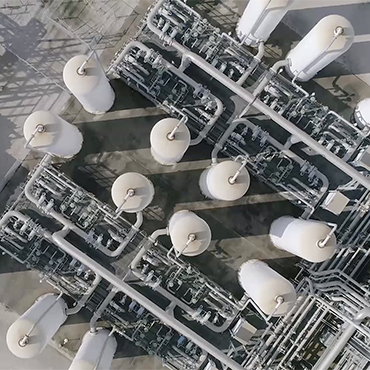

Our State-of-the-Art Facilities

Innovative Solutions for Reliable Helium Supply

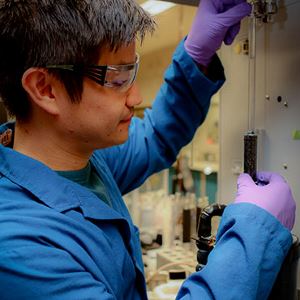

In addition, our one-of-a-kind helium production facility located in Doe Canyon, Colorado uses cutting edge technology, combined with world-class operations, to extract and produce helium.

The helium from these facilities strengthens and diversifies our helium supply chain to further enable the reliable delivery of product to our customers around the world.

Are you a potential technology partner?

At Air Products, we are committed to developing and deploying best-in-class technologies that keep us and our clients on the leading edge. If you believe that your technology can be a valuable asset to Air Products, or one of our technologies will give you an advantage, we encourage you to learn more.